By Andrew Knapper, Senior Implementation Specialist

An offshore oil production facility team’s success offers many lessons for event planning done right.

Shutdown Key Results:

- Incident free

- 33 hours earlier start-up vs plan

- 4.25 days ahead of budget

Value creation:

- +$2.7 million: early start-up resulted in 23,365 bbls of additional production

- +$8.7 million versus budget

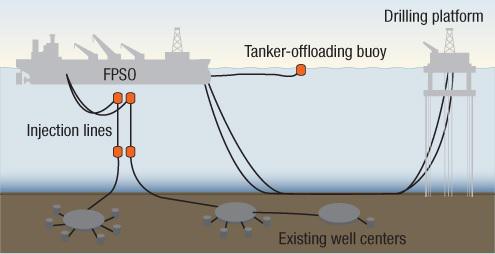

The Floating Production, Storage and Offloading (FPSO) operation and leadership team faced a real challenge with its upcoming Failure Mode Effect Analysis (FMEA) shutdown – they needed to demonstrate that they could get it right first time: within plan and budget, to the right quality and with zero accidents or incidents.

Failure mode effect testing sounds simple, but the risk to sensitive electronic equipment and systems is very high. This team faced three major ‘black-out’ tests in their FMEA testing: vessel shutdown forward, vessel shutdown aft and then an abandon ship shutdown.

RLG Performance coaches were already on-site working a longer-term improvement project, but to help this event team achieve top results, the RLG team members facilitated a TMP™ (Theoretical Maximum Performance) planning optimization session with a small asset and vendor team, followed by Front Line Planning (FLP™) sessions on emergent scope and changing conditions planning.

What is TMP™?

TMP™ is the result of ‘perfect execution in all phases, stages and steps of a plan or process.’ Its objectives are simple but facilitation takes experience to get valuable engagement and progress leading to tangible outcomes:

- Gather together an appropriate cross functional team

- Create small, focused teams to analyze schedule blocks

- Identify causes and issues

- Pinpoint risks and opportunities

- Set priorities and actions

Using TMP™ to engage teams to review their plans, increases their ability to safely deliver the shutdown on time. In this case, the team identified their need to conduct additional FLP™ sessions offshore, including those personnel and vendors and targeting specific small work scopes.

What Results Came from TMP™ and FLP™?

The large TMP™ workshop and four smaller FLP™ sessions resulted in:

- 54 separate actions which, when completed, would directly influence safety, duration or cost

- Very high engagement and ownership of the resulting plans

- Stronger communication, coordination, and commitment to the clearly identified actions between the vendors, offshore and onshore teams

- A commitment to using Real-Time Lessons Learned (RTLL™) to identify and manage shutdown risks, and quickly implement improvements during the event to capture gains

- A practical commitment to safe work due to the familiarity gained of the work scope and team involved

Taking into account the major advance preparation, planning and complexity of the above workscope, in particular the ESD Level 0/1A/1B testing and associated re-instatement upon completion of testing, this should be considered to be a major achievement by all to complete this work both incident free and over a day ahead of schedule.’

C&I Engineer

What Was Done Differently?

The offshore operations engineers’ and shutdown coordinator’s challenge at on the onset was to ensure the team had robust plans, had completed their actions, had all the necessary materials and resources, and understood their activities. The planning sessions helped these, but together, the onshore and offshore teams, vendors, and project owners agreed upon additional steps:

- One combined action tracker with HIRA (Hazard Identification and Risk Assessment) and TMP™ actions, reviewed daily up to and during the event

- Weekly coordination calls before the event, and a structured daily call during the event

- Six additional FLP™ sessions on emergent and unclear scope while offshore during the event

- Stage gates and a KPI dashboard for planning readiness

"It’s been an overall great team effort onshore and offshore! It demonstrates that as a FPSO team we’re moving in the right direction."

"This has been a remarkable outage: no leaks and incident free; completed 33 hours early; 72 planned activities out of 73 completed; 10 opportune scopes completed; 5,000 manhours of work liquidated; and ESD level 0 initiated and recovered from. A great effort all around — a tremendous achievement for the team."

FPSO OIM

Imagine duplicating these results in your facility. While this story is specific to one critical, high-value event, this organization embraced optimization and learning processes to achieve greater results as a team.

We would love to talk to you about your challenge. We have more stories to share, details on how we work with clients, and would enjoy talking through your specifics. We also have event process and readiness assessments, which can be conducted remotely, on-site or by a hybrid solution. Contact us.