Author: Rob Gulbronson

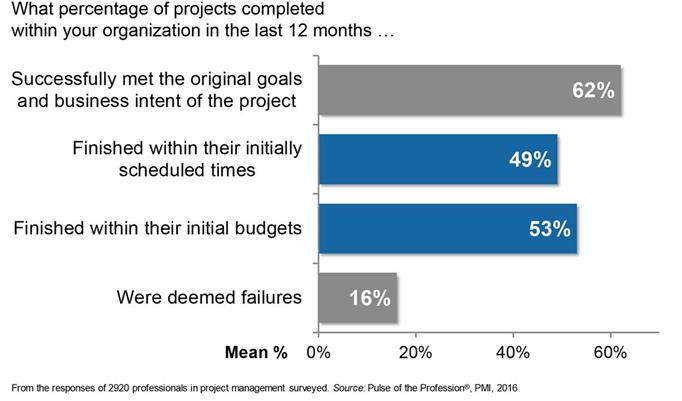

“Over half of capital projects fail to meet their original schedule,” claims a recent study by the Project Management Institute (PMI®), “and organizations waste US$122 million for every US$1 billion invested due to poor project performance.”

From our experience, a leading cause of project delay is the failure to complete detailed, quality engineering on time.

One recent RLG petrochemical client recognized this risk and asked RLG to support their Engineering, Procurement and Construction (EPC) partner, a multi-national engineering and construction firm, during the design phase of a large capital project. Historically, project engineering lagged up to 30% behind schedule, causing costly delays and considerable frustration throughout the project organization.

Working with RLG, this same EPC was able to deliver the detailed engineering on-time. So why the dramatic change?

We quickly realized that this EPC was well prepared to do the engineering, but not structured to manage performance effectively. This is a big difference and requires a different approach and skill set.

This project, like most we encounter, required a performance management program involving four steps:

- Determine leading indicators for schedule predictability: Project variance notices (PVNs) and weekly scopes of work completed are two examples of leading metrics that were identified and tracked. The EPC engineers used these leading metrics to identify gaps in performance on a weekly basis, rather than waiting several weeks after the end of the month to realize their performance was not meeting expectations.

- Involve each engineering discipline: Each group was given clear expectations on what quality looked like specific to their part of the design work. Further, by breaking their deliverables into weekly chunks, they were given clear expectations on their role in meeting schedule requirements.

- Develop an Operating Rhythm™ to regularly identify performance gaps and promote work group accountability for the action plan around them. These accountability forums primarily took two forms:

- A daily “huddle” within each engineering discipline to reinforce expectations and track daily the work completed compared to schedule. The various engineering disciplines used this meeting to identify gaps and to develop immediate actions plans to close them before the end of the week.

- A weekly business review where engineering discipline leaders reported on group performance and addressed any variances to plan. This forum fostered cooperation among the various disciplines and helped to break down the previously existing silos.

- Positive recognition and milestone celebrations were built into the process to ensure that people took the time to recognize great performance and peer support.

In each step, RLG performance coaches were closely involved to establish the tools and processes to ensure full participation. We worked closely with leaders to build capability and confidence in these new interactions, and supported facilitation, analysis and execution of performance management events.

This four step process brought visibility to key indicators, stimulated accountability conversations amongst the work owners, and recognized the behaviors needed for success. For this EPC, it corrected the 30% lag in engineering deliverables and set the project up for success.

If this situation applies to your project, reach out to us. We can talk about how RLG can help your project meet schedule, cost and quality targets.