By Scott McKenzie

WHAT BIASES ARE WE TALKING ABOUT?

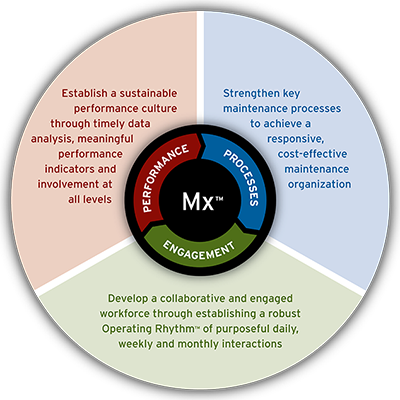

Achieving Maintenance Excellence™ in an organisation is as much about the culture as it is about the technology, tools and processes. Organisations can look to high-performing teams in the sports area to learn how to align and engage people in their maintenance excellence ambitions.

WHAT ARE MARGINAL GAINS?

Popularised by Dave Brailsford and the UK Olympic Cycling community, marginal gains was introduced to engage and align the entire cycling team towards improving their performance, in their case from the middle of the pack to the best team on the circuit. At its core, marginal gains is the hypothesis that focus on any gain in performance, however small, will accumulate and lead to step-change in results and outperform competition.

Dave shares the story of the UK cycling team using the same beds, pillows, and soap while on the road so that the athletes get as comfortable a sleep as possible as a marginal gain. Other examples include cross-functional collaboration on cycle mechanics, wheel alignment, standardization of meetings and action tracking across the cycling Olympic organization.

WHAT CAN BE DONE?

The concept of marginal gains can be used to align cross-functional groups in an organization towards the goal of maintenance excellence. Operations, Maintenance, Inspection, Supply Chain, Stores, Management, Procurement – all working in harmony to create the culture where it is okay to challenge and raise ideas (even outside your assigned area of direct responsibility).

Just like the UK cycling team, it can be used to get the best from every individual and align their ambitions with those of the organization. It gives permission for everyone to be on the lookout for marginal gains, and to take coordinated action to improve.

This approach is completely aligned with concepts such as continuous improvement and Lean Six Sigma, which may already be in place. Marginal gains will likely be more motivating culturally and people more easily relate to the picture of small gains adding up to a big improvement.

RLG’s Operating Rhythm™ is perfectly set up to instill the marginal gains concept and give the stages for people to get involved and engaged. These series of performance discussions, regularly set up across the organization, can be the drumbeat in which your marginal gains program takes root and thrives. It gives the platform where marginal gains can be discussed, agreed and actioned with a rigorous attention to detail.

We’ve seen improvements of more than 15% in cost and an increase of more than 5% in equipment reliability within 12 months of putting in place such a structured Operating Rhythm™.